PCB or printed circuit board design has flexed in recent years to accommodate fast-changing advancements in multiple areas from mobile phone innovation to medical equipment modernisation.

Here we look into the key elements of PCB design to identify why PCB design is developing and where it will go next.

What’s a printed circuit board?

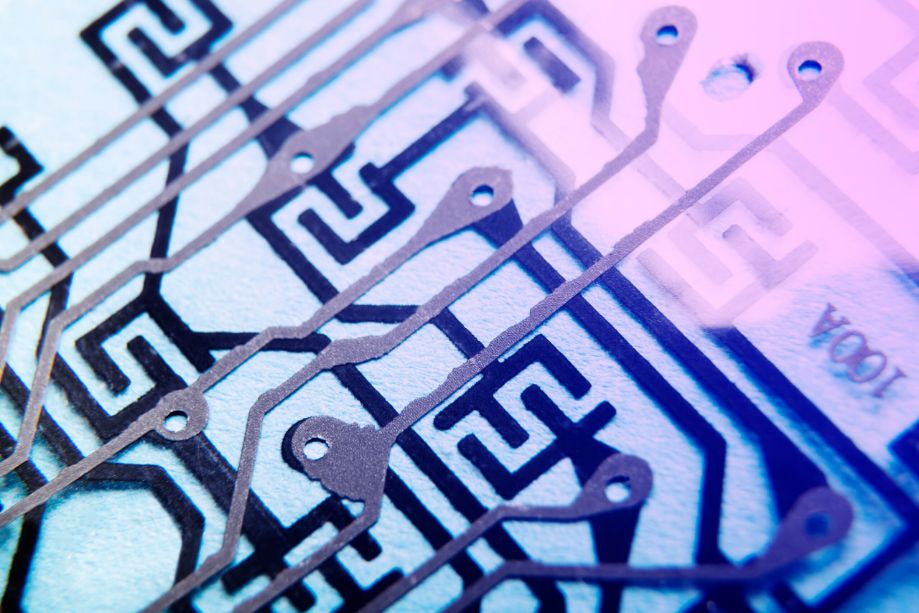

PCB or a printed circuit board refers to a solid structure that contains electronic circuits with embedded metal traces and larger metal planes. Components are soldered onto the board to enable interconnection and boards can be created with different layers of circuitry for variable uses.

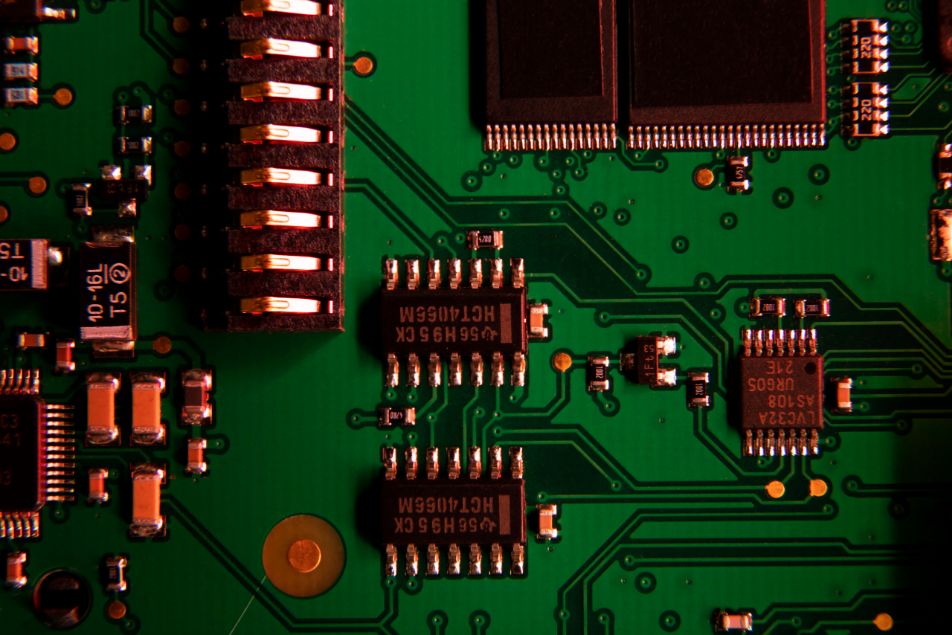

Once the board has been loaded with it’s components, it’s now a PCA (printed circuit assembly). Essentially, this means the board is completely populated and able to electrically function.

PCB class

Self-service systems incorporate a touchscreen computer or tablet linked to purpose-specific software

Printed circuit boards are generally allocated a class which indicates their quality and reliability levels:

- Class 1 PCB boards: used in consumer electronics – toys, flashlights.

- Class 2 PCB boards: used for dedicated service electronic products, such as air conditioners, TVs and computers.

- Class 3 PCB boards: designed for high reliability applications, such as medical, military and aerospace.

Boards can be created as rigid, flexible or metal core, depending on the client requirements for the board. Rigid boards are the most common using FR-4 material, essentially a fibreglass composite. However, flexible boards in more recent years gave attracted more attention, due their ability to work better in small spaces in and in complex shapes found in wearables.

Inside PCB design

Before the manufacture of printed circuit boards, a design process should take place using CAD (computer aided design) tools support this process. Development of PCB design involves two core categories: schematic capture for circuit connectivity and board layout. Schematic capture is linking components with nets, and layout is converting those nets and components into a physical design.

Once the design is complete it is exported in an industry standard format called a Gerber. This is the ‘artwork’ of the circuit board, and will be accompanied with a placement file and BOM (Bill of Materials).

4 Top PCB design trends 2023

Having worked with UK libraries for over 50 year

The global PCB market had a value of $78 billion in 2021 and is predicted to increase to $128 billion by 2030. Statistics that tell us just how valuable PCBs are to the growth of global economies over the next decade.

- Petite PCBs

Without a doubt, consumer electronics is dominated right now by smaller, more compact designs in wearables, mobile phones and other consumer devices.Creating smaller products inevitably requires lighter, more miniaturised printed circuit boards to ensure greater bendability, flexibility and enhanced performance.Increasing the compact nature of PCB design needs higher component density. To accomplish this target, PCB designers are often opting into smaller scale surface mount components on multilayered printed circuit boards to increase the density of components for pocket-sized product construction.

- Maximising new materials for PCB design

Innovative materials that alter the way printed circuit boards perform are entering the market at a stronger pace than ever before. Growing demands for smaller, more flexible electronic products are driving forward the incorporation of new materials in PCB design.Materials that are being exploited to match the rapid developments in this type of design include flexible substrates (thin, heat-resistant material made of polymers) and high-speed laminates (made from thin layers of fabric or fibreglass).Constructing PCBs with laminate boards that are thinner with fewer layers can result in more malleable boards that adapt efficiently to today’s compact and flexible products.

AdvaNova Consultancy create both standard and bespoke PCB designs, adhering to the client’s brief. If client’s need more flexible and proactive designs to suit their overall product, AdvaNova Consultancy’s inhouse design, manufacture and assembly team feature the insight and experience for challenging projects.

As our customers already know, AdvaNova Consultancy can deliver the most suitable PCB design and end-product finish specifically constructed to client instructions.

- Growing dominance of 5G technology

5G is really beginning to show its strength in the UK, with integration increasing in all regions. As 5G adoption becomes more widespread in terms of enhanced interconnectivity, many more PCB design companies are considering how to adapt and refine PCB design to keep up with 5G technology demand.If boards are going to be capable of withstanding and supporting 5G technologies, then they will need to be able to handle and control higher frequency signals, while reducing the risk of signal loss.An example of changing practices to accommodate 5G-capable PCB design is the modified semi-additive process (MSAP) technique, which enables better high circuit density in comparison to traditional etching.

Manufacturers can then use AOI (advanced automated optical inspection) early in the process to spot any potential issues with PCBs.

- Sustainability and energy efficiency

Reducing energy costs and creating power efficiencies throughout the whole manufacturing process are motivators for the majority of companies in 2023. Not only in their own production, but in the creation of more power-efficient PCBs. At Advanova Consultancy we use 100% renewable energy in our assembly line, as well as designing for low power.The inclusion of power-saving components can help PCBs become more cost and energy effective. PCB designers regularly use DC-DC converters to help improve power conservation and enhance productivity, however careful selection around buck-boost power supply can greatly increase efficiencies.

AdvaNova Consultancy is the home of smart PCB design

AdvaNova Consultancy are PCB design specialists who harness the power of IoT for your organisation. We have an in-house PCB production facility with a dedicated production team to meet your needs.

Our site includes automated in-line equipment with automated optical inspection at both solder paste and post-assembly points, multiple pick and place machines, plus cloud-based management and traceability.

Get in touch with us for a consultancy call to discuss your PCB design projects in more detail.